Technology

Breathe life into metal saws for our customer. The technology s...

Since our establishment, we have always honored the policy of "Accuracy first".

"Accuracy first" simply means that the quality of our products is expected to be good.

This policy is basic to our existence, without which we would no longer be MRT.

In order to maintain this, we continue to advance through human resource development and technical innovation.

Why MRT?

・Optimal process design

・You can choose materials

・Thorough inspection of all products

・Regrinding

・Confidence born from producer-retailer joint manufacturing

・In-house maintenance and development

The unique solution for heat treatment.

We have the latest technology at our Heat Treatment facilities.

MRT's original technology enables to provide HSS bar, plate, and board without any distortion.

MRT, where there is the Top Heat Treatment Solution.

Become a company loved by the world through social contribution.

As good corporate citizens, we will contribute to our society to get empathy from our dear neighbors.

We are also actively working to contribute to the international community.

MRT's technology

Breathe life into metal saws for our customer. The technology s...

The characteristic of Solid carbide products This meticulous ma...

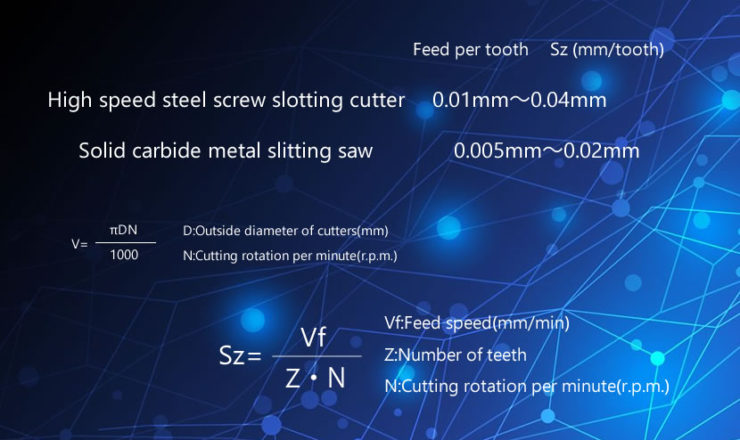

Cutting condition First, please enter the specs which you are u...

About TiN(Titanium Nitride) Coating Using Physical Vapor Dispos...

1.Reference Comparison Chart of the chemical contents and chara...

The following FAQ have been answered from the perspective of th...

MRT's QC

We specifically care about dimensional tolerance including that of metal-saw size and thickness. Distortions, warps or scratches can be causes of error. Our biggest mission is to not overlook such errors or scratches and to ensure that no products with such errors are delivered.

At MRT, inspections are conducted by each department and finally by the Inspection Division before delivery. The Inspection Division inspects all of the products we manufacture, rather than just doing spot checks. In accordance with the required accuracy for each product, we conduct not only inspections using micrometers, but also using cutting-edge inspection devices such as optical measuring instruments and non-contact measuring instruments.

Introduction of inspection equipment